Engineering and Fabrication GA5 Compressors

- Customer: Engineering and fabrication

- Reason for audit: Exploring the potential to replace two compressors with one single unit.

- Current compressor: 2 off Atlas Copco GA5

- Cost of electricity: £0.34 /kWh (average cost)

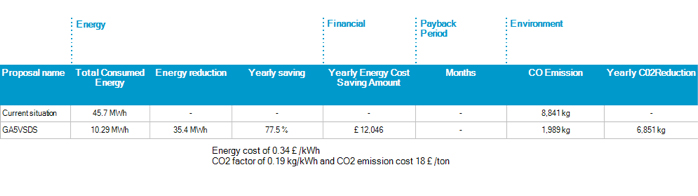

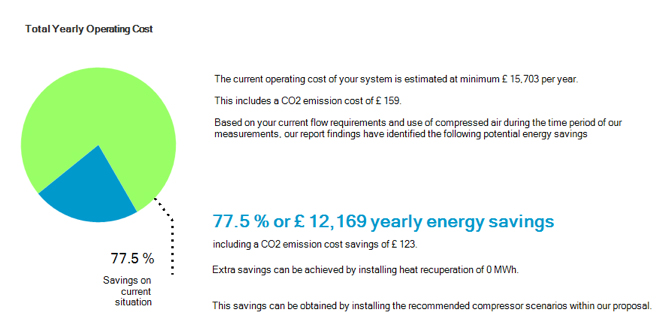

- Results of Audit: Measured potential savings 77.5% = £12,169/year

- Simulated compressor: Atlas Copco GA5VSDs (5kW) IE5

- ROI on equipment: <12 Months

How did this GA5VSDs compressor save so much energy and money?

Atlas Copcos state-of-the-art element in a unique vertical configuration with an ultra-premium efficiency (IE5) ferrite assisted synchronous reluctance motor. This new motor technology equals IE5 efficiency without the need of rare earth materials, making it a completely sustainable solution.

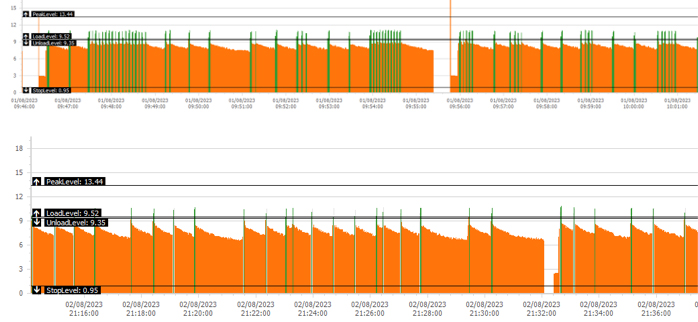

The energy (Amps) charts are showing the compressor running condition, running on load, running unloaded (not pumping air), and stopped.

Green is loaded running efficient use of power.

Orange is unloaded running, not producing air wasted electricity.

The compressors are a typical fixed speed units, they are both running independently and from the lack of green there is little efficient loaded running, we can see from the volume of off-load running, that there is great potential to save with a variable speed drive replacement.

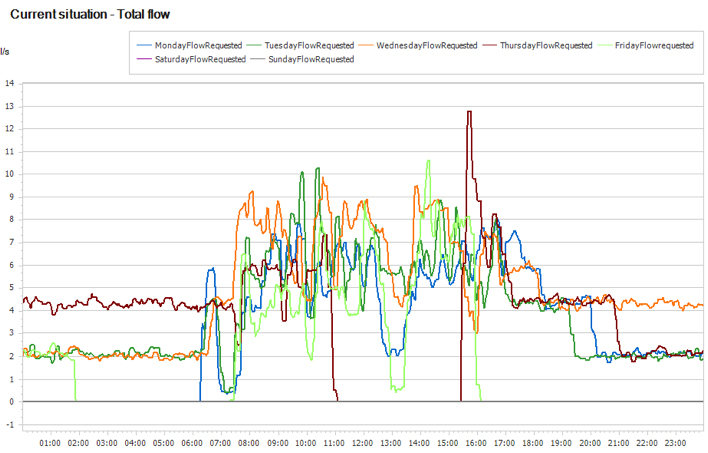

Weekly Flow chart (l/s)

Survey results