Sheet Metal Cutting and Fabrication G11

- Customer: Sheet metal cutting and fabrication

- Reason for audit: Fixed speed compressor, exploring savings

- Current compressor: Atlas Copco G11P (11kw)

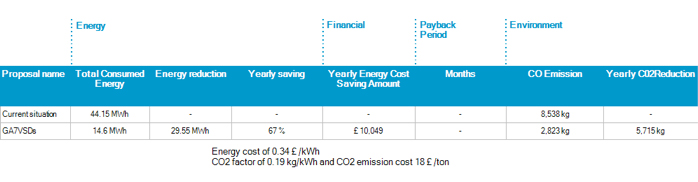

- Cost of electricity: £0.34 /kWh (average cost)

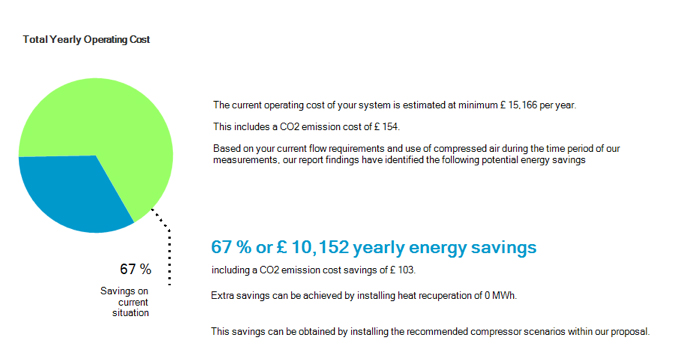

- Results of Audit: Measured potential savings 67% = £10,049/year

- Simulated compressor: Atlas Copco GA7VSDs (7kW) IE5

- ROI on equipment: 9 months

How did this GA11VSDs compressor save so much energy and money?

Atlas Copcos state-of-the-art element in a unique vertical configuration with an ultra-premium efficiency (IE5) ferrite assisted synchronous reluctance motor. This new motor technology equals IE5 efficiency without the need of rare earth materials, making it a completely sustainable solution.

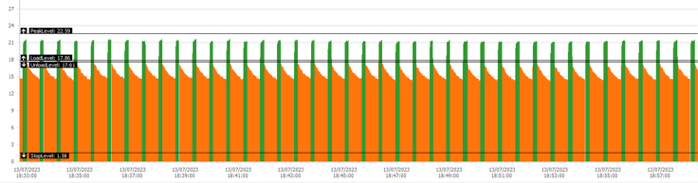

Green is loaded running efficient use of power.

Orange is unloaded running, not producing air wasted electricity.

The compressor is a typical fixed speed unit, currently a little oversized for the air demand and running normally, we can see from the volume of off-load running, that there is great potential to save with a variable speed drive replacement.

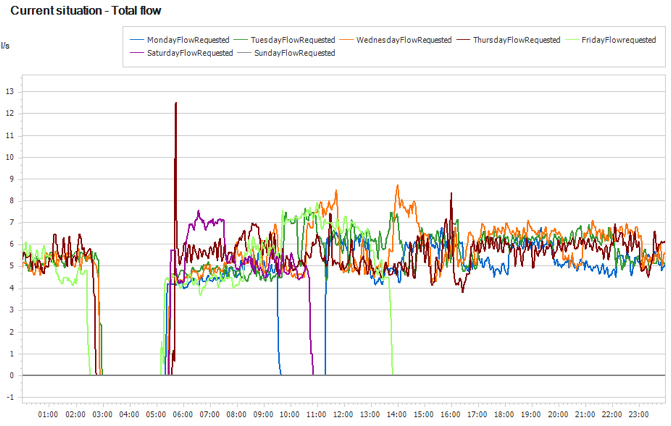

Weekly Flow chart (l/s)

Survey results