Research and development Facility Simulator HPC & Compair

- Customer: Research and development facility

- Reason for audit: Fixed speed compressors, reported by our site audit to appear unsuitable for the purpose.

- Current compressor: HPC BS51 & Compair L23RS

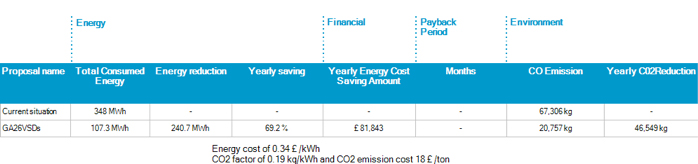

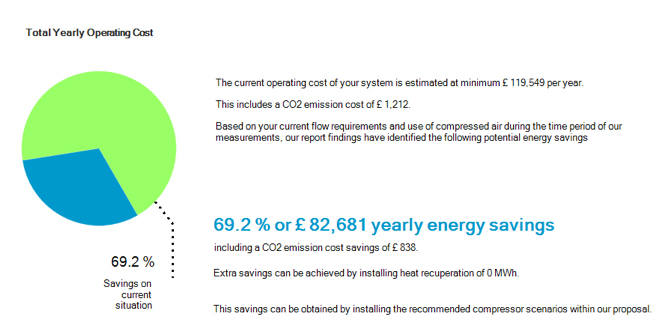

- Cost of electricity: £0.34 /kWh (average cost)

- Results of Audit: Measured potential savings 69.2% = £82,681/year

- Simulated compressor: Atlas Copco GA26VSDs (26kW) IE5

- ROI on equipment: <4 Months

How did this GA26VSDs compressor save so much energy and money?

Atlas Copcos state-of-the-art element in a unique vertical configuration with an ultra-premium efficiency (IE5) ferrite assisted synchronous reluctance motor. This new motor technology equals IE5 efficiency without the need of rare earth materials, making it a completely sustainable solution.

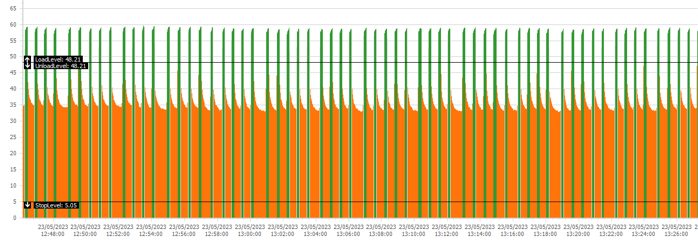

HPC

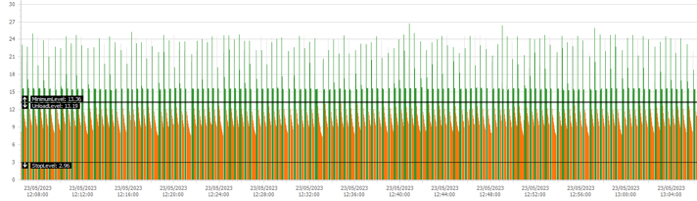

Compair

Green is loaded running efficient use of power.

Orange is unloaded running, not producing air wasted electricity.

We can see that due to the low demand, the variable speed drive Compair is actually offload running as the demand was below its lowest turn down speed, this is a common issue with many variable speed compressor brands, which is why it is vital to use the correct compressor for the application. Always ask if a variable speed compressor will unload if the demand is lower than the compressors lowest speed/flow as even you could still be wasting energy during low demand times.

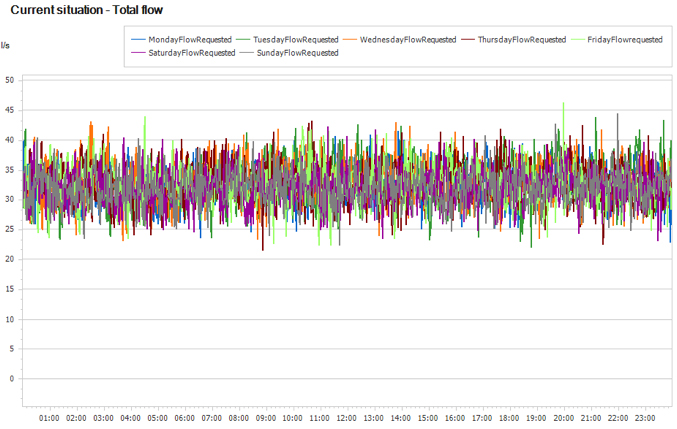

Weekly Flow chart (l/s)

Survey results