Customer: Engineering and fabrication

Reason for audit: Exploring the potential to replace four compressors with one single unit

Current compressor: Atlas Copco GA18+ (18.5kw), GA30VSD+, GA11, G11

Cost of electricity: £0.34 /kWh (average cost)

Results of Audit: Measured potential savings 55.6% = £33,433/year

Simulated compressor: Atlas Copco GA37VSDs (37kW) IE5

ROI on equipment: <12 Months

How does this GA37VSDs compressor save so much energy and money?

Atlas Copco’s state-of-the-art element in a unique vertical configuration with an ultra-premium efficiency (IE5) ferrite assisted synchronous reluctance motor. This new motor technology equals IE5 efficiency without the need of rare earth materials, making it a completely sustainable solution.

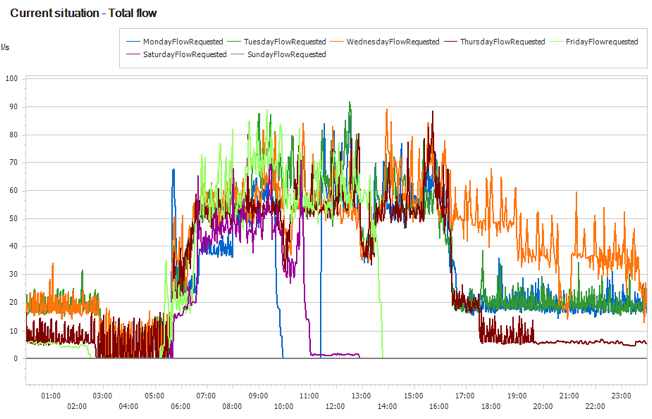

From the data collected from each compressor using synchronised iiTrack logging devices, we can create a combined compressed air flow profile.

You can see from the chart below that the compressed air is required 24 hours a day and has a very varied consumption which is ideal for a Variable Speed Drive (VSD) compressor.

Weekly Flow chart (l/s)

Survey results