VSD : Ultimate Energy Saver

Industry -leading Performance

- Industry-leading Free Air Delivery and low energy consumption.

- High Efficiency motor in combination with efficient element.

- Low noise emission suitable for workplace installation.

- Environmentally-friendly integrated dryer reduces footprint and pressure drops.

- Smart Elektronikon® graphic compressor controller with high-definition color display.

Premium Compressor

- High performance Free Air Delivery.

- High Efficiency motor in combination with highly efficient element.

- Premium quality at the lowest initial investment.

- Efficient environmentally-friendly integrated dryer reduces footprint and pressure drops.

- Ensured efficiency of Elektronikon® controller with connectivity.

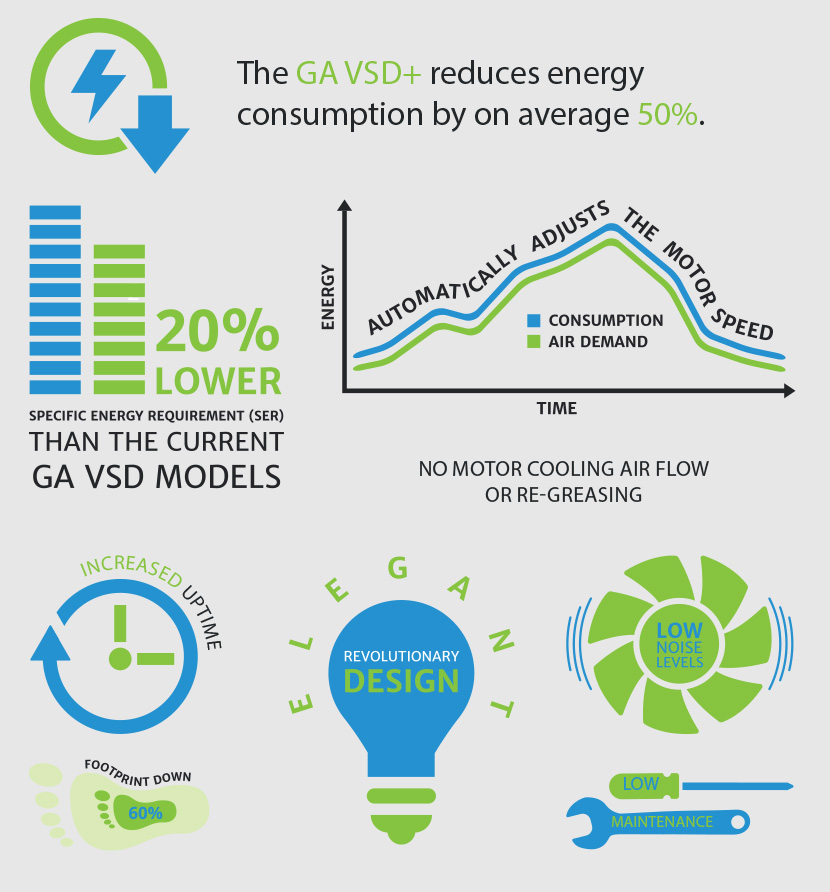

VSD: Driving down your energy costs

Over 80% of a compressors lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plants total electricity bill. To cut your energy costs, Atlas Copco pioneered Variable Speed Drive (VSD) technology in the compressed air industry. VSD leads to major energy savings, while protecting the environment for future generations. Thanks to continual investments in this technology, Atlas Copco offers the widest range of integrated VSD compressors on the market.

Why Atlas Copco Variable Speed Drive technology?

- On average 35% energy savings during fluctuations in production demand with an extensive turndown range.

- Integrated Elektronikon® Graphic controller controls the motor speed and high efficiency frequency inverter.

- No wasted idling times or blow-off losses in normal operation.

- Compressor can start/stop under full system pressure without the need to unload with special VSD motor.

- Eliminates peak current penalty during start-up.

- Minimizes system leakage due to a lower system pressure.

- EMC Compliance to directives (2004/108/EG).

In almost every production environment, air demand fluctuates depending on different factors such as the time of the day, week or even month. Extensive measurements and studies of compressed air demand profiles show that many compressors have substantial variations in air demand.

on average 35% energy savings

Atlas Copcos VSD technology closely follows the air demand by automatically adjusting the motor speed. This results in on average 35% energy savings. The lifecycle cost of a compressor can be cut by an average of 22%. In addition, lowered system pressure with VSD dramatically minimizes energy use across your production.

How VSD technology saves energy

Contact your local Atlas Copco representative for an audit of your compressed air system. A real-time measurement simulation and audit report can be provided with recommendations for additional savings and sizing to meet your compressed air needs.